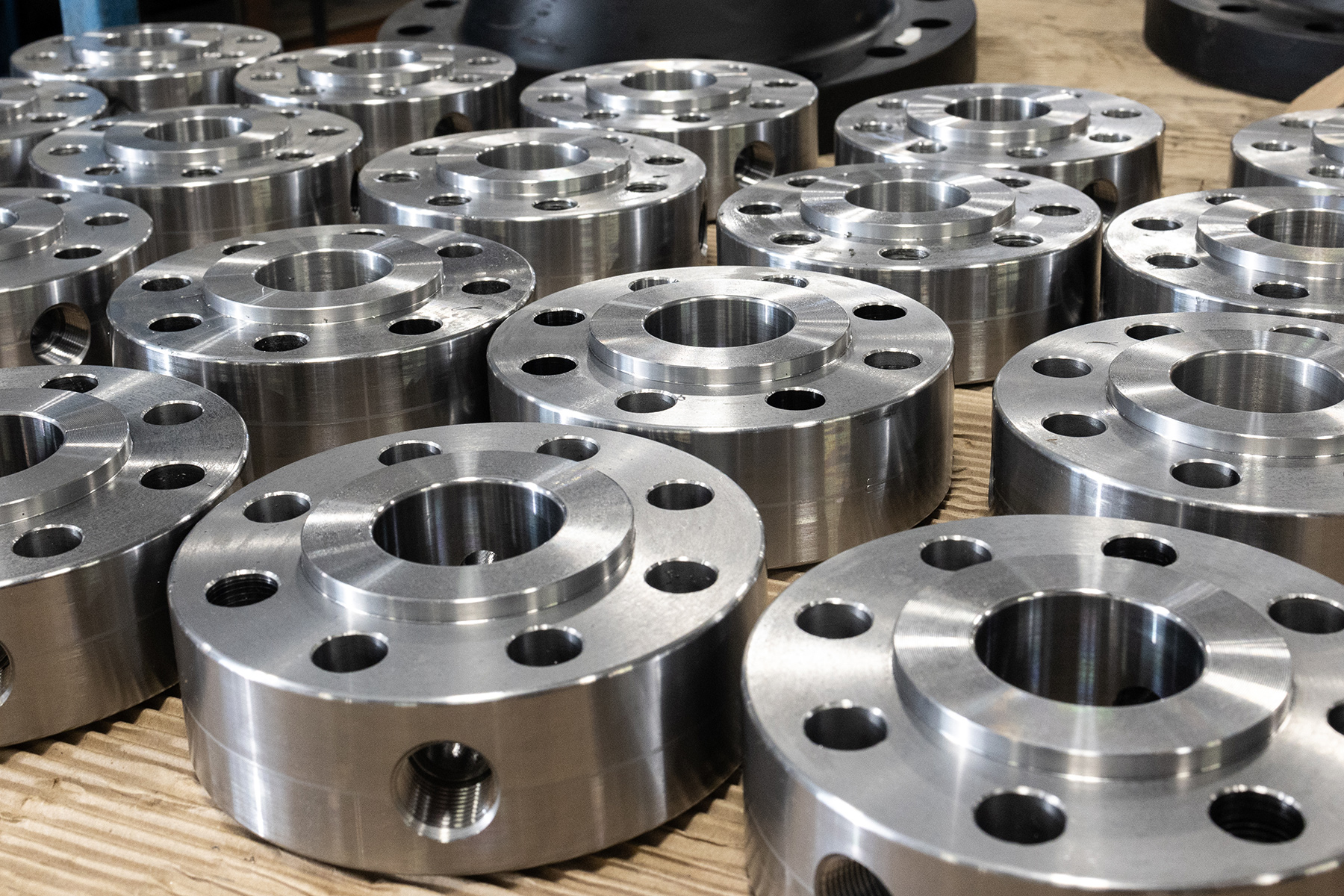

Our bleed and flush rings can be modified for your specific application or process line requirements

American Thermowell flush rings are available in variety of bores including concentric, eccentric, reducing concentric and reducing eccentric style.

Our Flush Ring design is made to accept all flanged pressure transmitters on one side and a standard ANSI flange on the other side in all sizes. An example of this would be as follows; 2” thick can come with two different ANSI sizes on each side allowing for example a 2” 150# process to fit with a 3” 150# level transmitter.

American Thermowell bleed rings are manufactured in house as well, and can be modified for your specific application or process line requirements. Bleed rings may also be referred to as calibration rings or drip rings, but they all do the same thing.

Face Styles

- Flat Face

- Raised Face

- Ring Type Joint (RTJ)

Exotic Materials & Coatings for Bleed and Flush Rings

We have experience manufacturing bleed and flush rings in a wide range of exotic and corrosion-resistant materials to suit demanding service conditions. Materials used include Super Duplex, Chrome-Moly, Hastelloy, 304/304L & 316/316L Stainless Steels, Carbon Steel , Monel, Inconel, Titanium, and Kynar just to name a few.

To further enhance performance and service life, available coatings and surface treatments include PTFE coatings for chemical resistance, electroless nickel plating (ENP), zinc or phosphate coatings, passivation, and specialized corrosion- or wear-resistant coatings as required by the application.

All rings are quality checked and tested to code, prior to being shipped

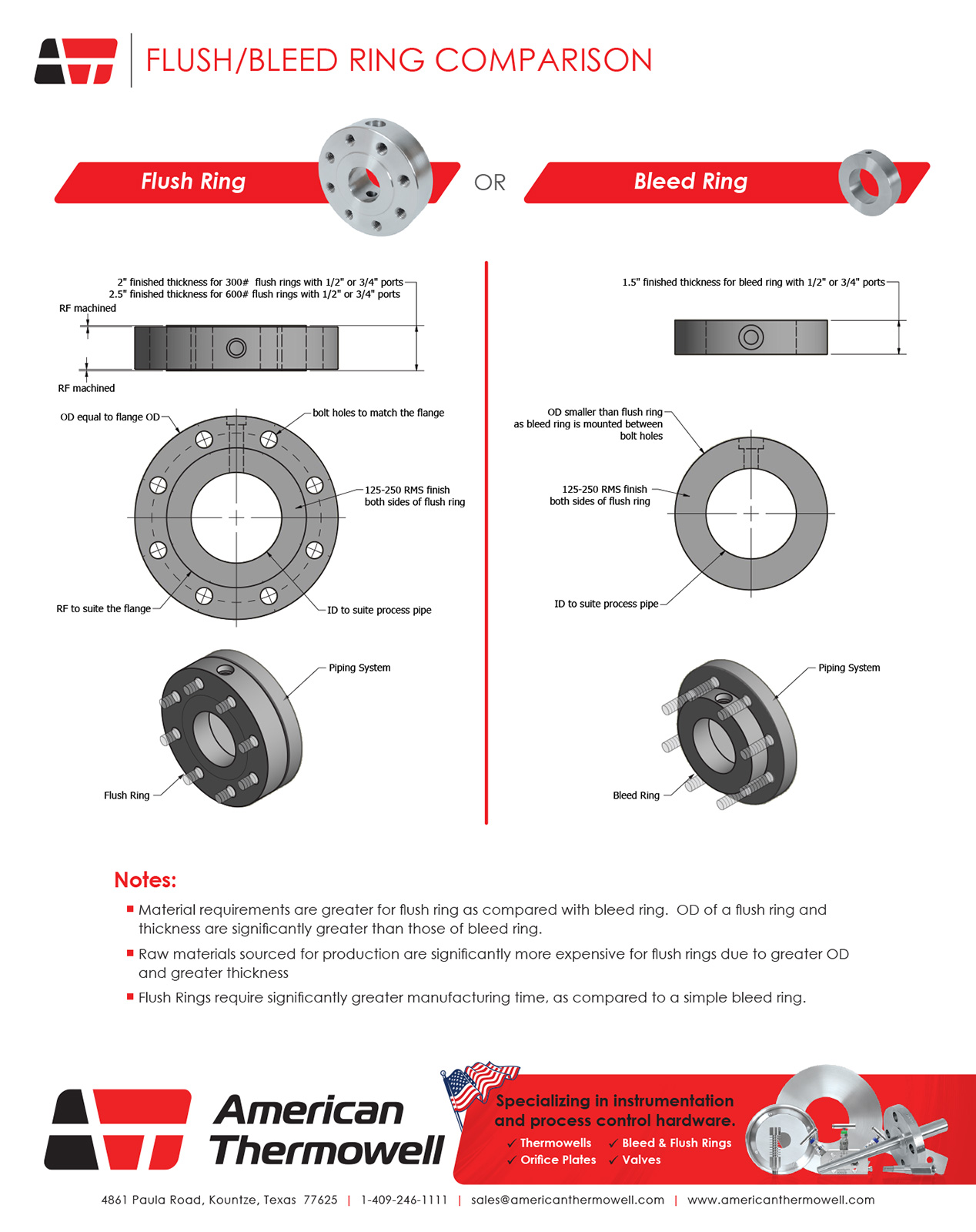

What’s the difference between Bleed and Flush Rings

Even though they look similar, these two products are very much different. Looking at the installation type, required materials and the manufacturing time. Cost is going to be one of the biggest differences between these two products, so it’s best to make sure you’re ordering the right product for the job.

- Material requirements are greater for flush ring as compared with bleed ring. OD of a flush ring and thickness are significantly greater than those of bleed ring

- Raw materials sourced for production are significantly more expensive for flush rings due to greater OD and greater thickness

- Flush Rings require significantly greater manufacturing time. Raised face, bolt holes require additional machining time as compare to simple bleed ring

Precision | Quality | On-time Delivery

American Thermowell manufacturers all bleed and flush rings, with over 25 years experience manufacturing the hardware to the temperature, flow and pressure industries. These rings are designed to mount between the flanged process connection and the diaphragm seal, which then allow easy access for on site calibration, venting & purging.

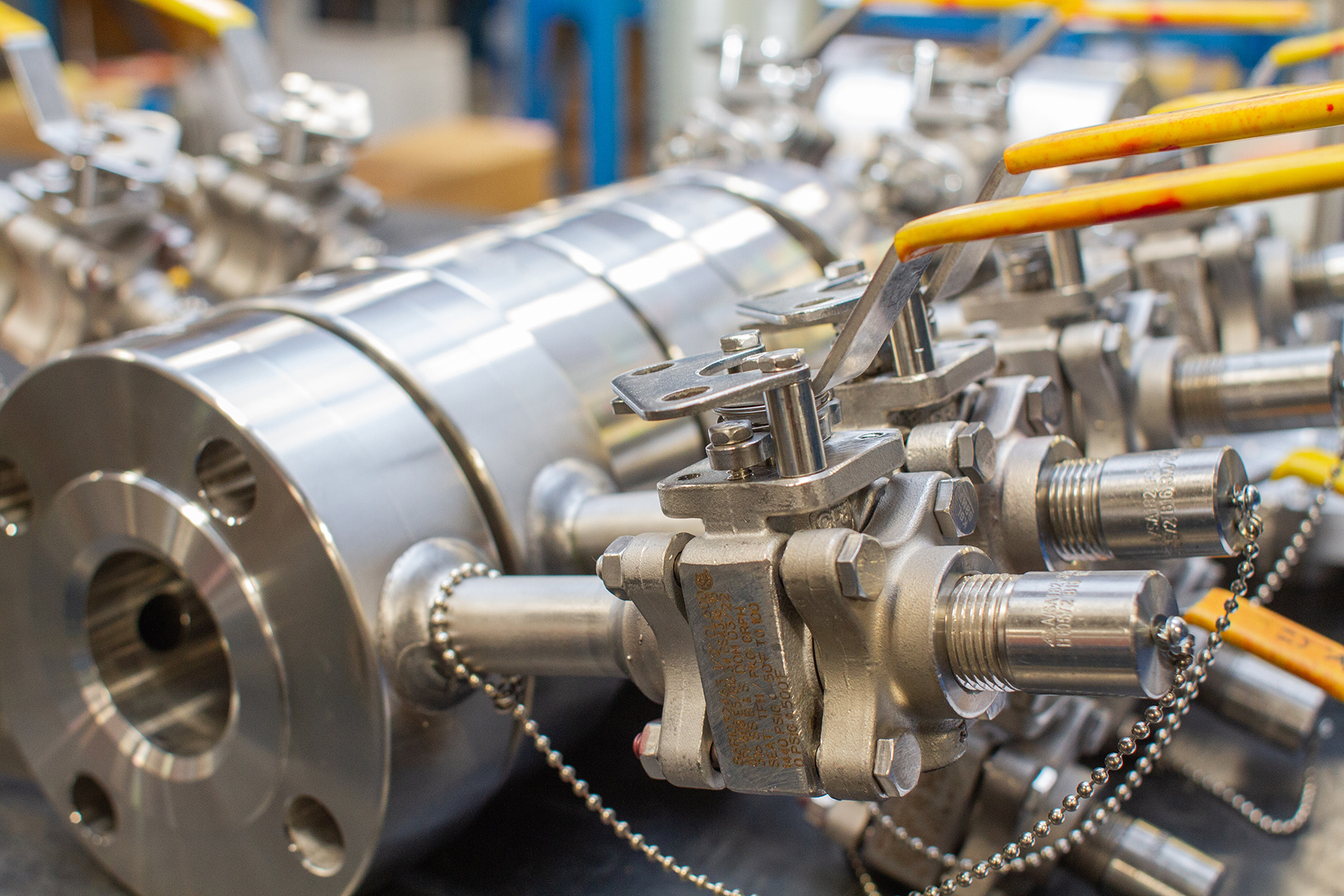

Bleed Rings

- Available in both threaded and socket-weld designs.

- Manufactured in accordance with ASME, ASTM and ANSI standards.

- CRN numbers available if requested.

- Single or double valve assemblies available.

- Flange assemblies also available.

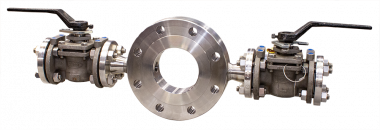

Flush Rings

- Allows for transmitter calibration, venting and purging.

- The seal and process size transition design reduces installation and maintenance costs.

- Our engineered and manufactured-in-house design can be adapted and modified for your specific application.

- Eliminates the need for a reducing spool.

- Valve options available upon request.